“WIRE CONNECTORS AND SOLDERING

LUGS (ZMVV)

USE

This category covers single-polarity wire connectors for use with all

alloys of copper, aluminum, or copper-clad aluminum conductors, or all

three, for the purpose of providing contact between current-carrying parts.

Wire connectors may be uninsulated, supplied with integral insulation, or

separable insulation in the form of insulating caps or covers.

Terminal connectors establish a connection between one or more conductors

to a terminal plate or stud, or to any similar device by means of

mechanical pressure. They are fixed in position.

Splicing wire connectors establish a connection between two or more

conductors by means of mechanical pressure and are not intended to be

permanently mounted. They are floating, such as a twist-on connector in

an outlet box.

Insulating caps or covers are for general use when installed on specific

connectors. Information covering use of the caps or cover on specific connectors

appears on the unit containers in which the caps or covers are

packaged.

Soldering lugs are terminal connectors designed for attachment to a

conductor by means of solder (nonpressure).

Reusability — Wire connectors have not been investigated for reusability.

Reusability should be determined by the installer and the Authority

Having Jurisdiction.

Direct burial — Wire connectors have not been investigated for direct

burial. See RELATED PRODUCTS below.

Use in service equipment — Where wire connectors are used as a part

of service equipment, dead-front switchboards, panelboards, meter sockets,

enclosed switches, circuit breakers, etc., reference should be made to

the General Information for those categories concerning the use of the

wire connectors. When wire connectors suitable for use with aluminum or

copper-clad aluminum conductors are employed in such equipment, the

suitability for wiring with aluminum or copper-clad aluminum conductors

of such equipment will be indicated by a marking on the equipment and

is independent of any marking on the wire connector.

INSTALLATION

Wire connectors are intended for use in installations covered by ANSI/

NFPA 70, ‘‘National Electrical Code’’ (NEC), and should be installed using

the prescribed manufacturer’s installation instructions.

Stacking of connectors (multiple connectors assembled using a single

bolt, nut and washers) may be permitted where mechanical interference is

reduced or eliminated with the use of offset tangs, stacking adapters, and

the like. The surface contact area of the mounting tang should make complete

contact with the mounting surface or the previously stacked connector

tang.

PRODUCT MARKINGS AND RATINGS

Wire size and wire combinations — Wire connectors are rated for 30

AWG or larger copper conductors and/or 12 AWG or larger aluminum or

copper-clad aluminum conductors. The wire size, wire range or wire combinations

are marked on the connector, or on or within the unit container.

Wire connectors additionally investigated for metric-size conductors are

marked with the metric wire sizes expressed in mm2.

Multiple conductors — Connectors generally accommodate a single conductor

under a clamping mechanism unless otherwise identified, such as

with the number of conductors located parenthetically in front of the wire

size or range. Some connectors may have a single-conductor wire range as

well as a second multiple-conductor wire range. Some connectors, such as

twist-on connectors, will have multiple conductors expressed in a list of

wire combinations.

Parallel conductors — Connectors intended for paralleling of conductors

are intended to be used in accordance with Clause 310.4 of the NEC. Parallel

connectors may have multiple-conductor clamping mechanisms, each

accepting a single conductor or a singular clamping mechanism accepting

multiple conductors.

Wire stranding — Unless clearly marked ‘‘Solid,’’ ‘‘SOL,’’ ‘‘Stranded’’ or

‘‘STR’’ for a given wire size, wire range or wire combination, conductors

in the range 30-10 AWG are both solid and stranded, and 8 AWG and

larger are for stranded wire only. Connectors additionally rated for metric

conductor sizes may be marked with the letter ‘‘r’’ for rigid solid and

rigid stranded conductors, or the letter ‘‘f’’ for flexible conductors.

Wire Connectors and Soldering Lugs (ZMVV)-Continued

Stranded conductor Class — Connectors rated for use with stranded conductors

are for the following strand configurations: Aluminum – Class B concentric, compressed or

compact, and SIW (single input wire) Copper-clad aluminum – Class B concentric or compressed, and Class

C concentric Copper – Class B concentric or compressed, and Class C concentric

Wire connectors additionally rated for use with compact copper conductors

are additionally marked ‘‘For compact-stranded copper conductors’’ or

equivalent on the connector, or on or within the unit container.

Wire connectors additionally rated for use with other Class conductors,

such as Class M, are marked on the connector, or on or within the unit container

or information sheet within the unit container with the additional

class designation and number of strands.

Strip length — Some connectors or their unit containers are marked with

a strip length for the conductor before assembly to the wire connector.

Conductor material — Wire connectors or the unit containers are marked

with the type of conductor material(s) as follows:

Marking

(or equivalent) For Use With

‘‘CU’’ Copper wire only

‘‘AL’’ Aluminum wire only

‘‘AL-CU’’ or ‘‘CU-AL’’ Copper to copper,

aluminum to aluminum,

copper to aluminum but not intermixed or in direct

physical contact,

copper-clad aluminum to copper-clad aluminum,

copper to copper-clad aluminum,

aluminum to copper-clad aluminum but not intermixed

or in direct physical contact

‘‘AL-CU (intermixed – dry

locations)’’

Copper to copper,

aluminum to aluminum,

copper to aluminum intermixed and in direct physical

contact,

copper-clad aluminum to copper-clad aluminum,

copper to copper-clad aluminum,

aluminum to copper-clad aluminum and in direct

physical contact.

Except as otherwise noted on or in the shipping carton, aluminum conductors

are not intended to be used in direct physical contact with copper

and copper-clad aluminum conductors in the same connector. A wire connector

for securing an aluminum wire in combination with a copper or

copper-clad aluminum conductor, where physical contact occurs between

the wires of different metals, is limited to dry locations only and is marked

‘‘AL-CU (intermixed – dry locations).’’

Ampacity level rating:

A. Equipment use — Equipment wiring requirements may restrict the sizing,

ampacity and temperature ratings of connected conductors. Equipment

requirements may limit 90°C or higher-rated conductors to 60 or

75°C ampacity in accordance with Electrical Equipment for Use in

Ordinary Locations (AALZ).

B. General use — Connectors rated 75°C are intended for use at ampacities

not greater than those for 75°C-rated conductors, and connectors

rated 90°C are for use at ampacities not greater than those for 90°Crated

conductors. Connectors may be marked with ‘‘75C’’ or ‘‘90C’’ to

represent these levels. Alternatively, these rating levels may be represented

by a 7 or 9 associated with the marking ‘‘CU,’’ ‘‘AL’’ or ‘‘ALCU,’’

e.g., ‘‘AL9,’’ ‘‘AL9CU,’’ ‘‘AL7CU,’’ ‘‘CU7,’’ ‘‘CU9.’’ Connectors

not marked with an ampacity number 7 or 9 have an assumed level

per the following table. Use of higher-temperature-rated conductors is

not prohibited, provided the ampacity levels continue to be based on

the 75 or 90°C ratings.

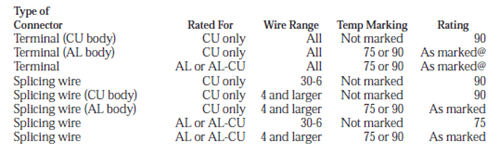

Connectors are rated and marked as follows:

@ Terminal connectors rated for 6 AWG or smaller conductors may have

the markings on the connector, the unit container, or on an information

sheet packed in the unit container.

Insulation temperature rating (maximum operating temperature) — Insulated

connectors, insulating caps and insulating covers have an insulation

temperature rating marked on the device or the unit container. Insulated

connectors, insulating caps and insulating covers that have an insulation

temperature greater than the connector ampacity level rating are marked

‘‘Temperature Rating of Insulating Material ___°C.’’

Voltage rating — Uninsulated wire connectors are rated for general use in

circuits up through 2000 V. Uninsulated wire connectors may be used in circuits

over 2000 V up through 35,000 V where the effects of corona have

been investigated in the end-use application. Uninsulated wire connectors

are not marked with a voltage rating.

Insulated wire connectors, insulating caps and insulating covers have voltage

ratings for which they have been found acceptable. The voltage rating is

marked on the device or the unit container and may be stated as ‘‘300 volts

maximum,’’ ‘‘600 volts maximum,’’ or ‘‘600 volts maximum building wire,

1000 volts maximum, in signs or luminaires,’’ or equivalent wording.

Flammability rating — Insulated connectors and insulating caps and covers

may be additionally marked with a flammability rating of V-2 or VTM-2

or better.

Assigned torque rating — A connector or its unit container may be

marked with an assigned torque value for which the connector was investigated.

INSTALLATION INSTRUCTIONS

Use of specific tools — A specific tool and die used to assemble a wire

connector to a conductor is identified on the connector, or on or within the

unit container of the connector. The identification consists of a catalog or

type designation, color-coding, die index number, or equivalent means.

Color-coding of the crimp barrel is common.

Multiple crimping operations — The number of crimps necessary to

make a connection using the specific tool is identified on the connector, or

on or within the unit container of the connector. Location and number of

crimping points is commonly located on the crimp barrel of the connector.

Conductor strip length — Wire connectors requiring a specific strip length

have this information identified on the connector, on or within the unit container

of the connector, on an insulating cover, or on the tool or tool carrying

case. Strip-length marking is optional for some constructions.

Preliminary preparation of conductor — Some wire connectors supply

instructions for the preliminary preparation of conductors, such as use of

conductor termination compound (antioxidant compound) or pre-twisting of

conductors, on or within the unit container.

Pre-twisting — Some connectors may specify that conductors are to be

pre-twisted before assembly onto the connector.

Conductor termination compound — Some connectors are shipped prefilled

with conductor termination compound (antioxidant compound). For

non-prefilled connectors, conductor termination compound may be used if

recommended by the connector manufacturer as preliminary preparation of

the conductor. Wire brushing of the conductor may also be performed if recommended.

Also see Conductor Termination Compounds (DVYW).

PRODUCT IDENTITY

One of the following product identities appears on the product:

Soldering Lug

Splicing Wire Connector

Terminal Connector

Wire Connector

Other product identities may be used as shown in the individual certifications.

RELATED PRODUCTS

Sealed wire-connector systems intended for direct burial, below-grade use,

or similar damp or wet locations are covered under Sealed Wire-connector

Systems (ZMWQ).

Wire-connector adapters installed on the end of a conductor prior to their

subsequent connection to certified wire connectors or to connectors used in

certified equipment are covered under Wire-connector Adapters (ZMOW).

ADDITIONAL INFORMATION

For additional information, see Electrical Equipment for Use in Ordinary

Locations (AALZ).

REQUIREMENTS

The basic standards used to investigate products in this category are

ANSI/UL 486A-486B, ‘‘Wire Connectors,’’ and ANSI/UL 486C, ‘‘Splicing

Wire Connectors.’’

UL MARK

The Certification Mark of UL on the smallest unit container in which the

product is packaged, with or without the UL symbol on the product, is the

only method provided by UL to identify products manufactured under its

Certification and Follow-Up Service. The Certification Mark for these products

includes the UL symbol, the words ‘‘CERTIFIED’’ and ‘‘SAFETY,’’ the

geographic identifier(s), and a file number.

Alternate UL Mark

The Listing Mark of UL on the smallest unit container in which the product

is packaged, with or without the UL symbol on the product, is the only

method provided by UL to identify these products manufactured under its

Listing and Follow-Up Service. The Listing Mark for these products

includes the UL symbol (as illustrated in the Introduction of this Directory)

together with the word ‘‘LISTED,’’ a control number, and one of the

following product names: ‘‘Wire Connector,’’ ‘‘Soldering Lug,’’ ‘‘Terminal

Connector,’’ ‘‘Splicing Wire Connector,’’ or other appropriate product

name as shown in the individual Listings.

* * * * * * * * * * * * * * * * * * * * * * * * *

UL, in performing its functions in accordance with its objectives, does

not assume or undertake to discharge any responsibility of the manufacturer

or any other party. UL shall not incur any obligation or liability for

any loss, expense or damages, including incidental or consequential damages,

arising out of or in connection with the use, interpretation of, or reliance

upon this Guide Information.”

Ref: UL White Book UL.com |