Advancement International Ltd.

595 Circlewood, Aurora, OH 44202(USA)

Email: sales@LugsDirect.com

Phone: 330-562-8983 | FAX: 330-562-9990

|

Operated By: Advancement International Ltd. 595 Circlewood, Aurora, OH 44202(USA) Email: sales@LugsDirect.com Phone: 330-562-8983 | FAX: 330-562-9990 |

IHIConnectors |

Brumall Manufacturing Corp. |

Greaves Electrical Connectors |

Accepted forms of payment: |

||||||

ISO 9001 |

|

||||||||

FAQ

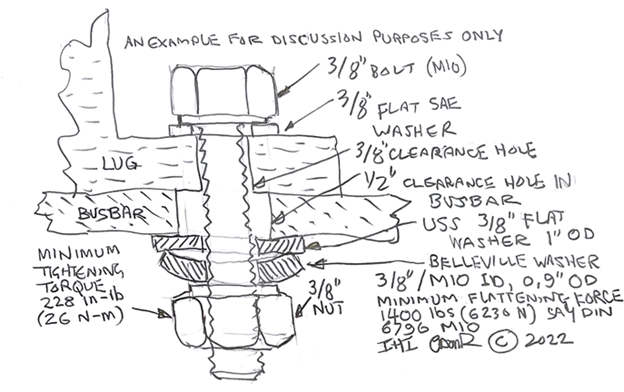

What is the best way to take a 3/8” bolt lug and bolt it to a ½” clearance hole in a busbar?

IHI cannot say what will or will not pass your field inspection scrutiny or what will work best in your unseen application.

That must be up to the user in each case to determine.

Answer #1

Use of the lug which has a native bolt hole that matches bus hole, but assuming that has been ruled out due to availability…….

Standard UL486 generally requires that the bolt used be “right sized” for the hole in the lug.

The purpose is that the assembly shall not come lose due to yielding of the standard washer reaching out over an overly large bolt clearance hole.

If the bus hole is bigger than standard clearance, it means that there a larger washer “reach distance” and more bowing/yielding of the thin standard washer is likely.

Answer #2

From a mechanical engineering point of view, using a hardened, thick washer (sold for this purpose- high clamping forces on soft materials) that will not yield and bow under the full customary bolt torque, in spite of the extra clearance “reach” distance, would solve the engineering concern that the soft, thin washer could yield over time and loose the clamping force to make the joint gas tight.

|

However, from a Standards Agency field inspection point of view, it gets into a grey area which could go either way, but by addressing the engineering concern, that goes a long way to mitigate concern.

Standards Agencies are of necessity prone to look at tested convention rather than innovation. So…… |

Answer #3

A more conventional way to do this in the same arena of cost as thick hardened washers could be use a Belleville spring washer and flat washer “pair” on the bottom of the part having the larger hole.

You have the option to use a Belleville and flat washer under the bolt head or nut under normal lug installation conventions if followed carefully. |

|

In fact, Belleville spring washers are recommended for thicker stacks and especially if thick aluminum is in the sandwich since more bolting force relaxation can occur from the expansion and contraction of thick metal sandwiches with high relative differential CTE (coefficient of Thermal Expansion rates) for steel copper aluminum.

The majority of bolted lugs installed, however, do not use Belleville spring washers, but it is an option commonly used in more demanding situations.

Testing on lugs such as IHI made lugs was done with no Belleville washers, only flat washers, “worst case” so you can use either with standard washers in “right sized holes” or Belleville washers, which are considered to be an upgrade since they provide compensation (take up) for more creep loosening than do standard washers.

The flat washer must contact the outer part of the Belleville washer, where it is fully supported by the copper bus and the inner hole in the Bellville washer is the same 3/8” nominal clearance size as the bolt.

This ensures that washers remain reasonably concentric with the common nominal size bolt.

So, when tightened, the Belleville acts as the cantilever spring washer to transfer the clamping force to the solid part around the ½” hole in the bus, in this one example.

This contrasts with the bolt head contact face or the nut contact face, that would be trying to bow/dish the thin, soft, standard washer into the oversize clearance hole.

Belleville washers are easier to find that have large OD for the relative size of the bolt hole, since they need a large diameter and increased thickness, to create their “cone spring washer” effect.

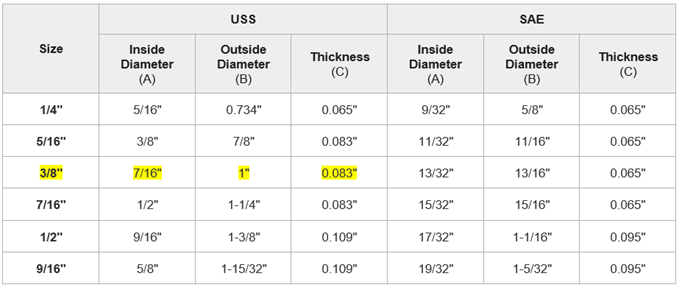

The periphery of the Belleville washer must be supported by a standard washer (say USS large OD style washers since the OD must be greater than the cone spring washer OD).

Using a properly configured cone spring washer set negates the issue with “washer bowing in the hole” and instead uses the solid ring of material around the larger hole.

Minimum clamping torques must be met and can be increased up to fully flattening the Belleville cone spring washer if the grade of bolt is adequate. The washer specification must meet the minimum spring flattening forces in the table below.

These correspond to the normal tightening force for Grade 2 bolts (working strength of Grade 2 bolts).

Whatever you decide to do should be carefully recorded with a detailed bill of material and an assembly procedure and verification of same, so that all proper care is taken to ensure your installations meet every intended condition.

Trial testing should be carried out including torquing the wire biding screw with no rotation of the lug body around the lug clamping screw bolt.

https://lugsdirect.com/Bolting-Listed-Lugs.htm

Hardware Typical for Bolting Listed Lugs to Bus Bars |

||||||

| Size of Steel SAE Bolt used UNC Class 2 or 3 Grade 2 or higher | Metric Bolt size used | Tightening torque Foot-lbs | N-m | If Belleville used, Minimum flattening force required (Pounds) | (N) | Flat Washer (plated steel or SS) 1 under bolt head (or Belleville) and 1 under nut |

| #8 | 1.5 | 2 | - | Yes | ||

| #10 | - | 2 | 3 | - | Yes | |

| 1/4 | M6 | 6 | 8 | 800 | 3,560 | Yes |

| 5/16 | M8 | 11 | 15 | 1000 | 4,450 | Yes |

| 3/8 | M10 | 19 | 26 | 1400 | 6,230 | Yes |

| 7/16 | - | 30 | 41 | 2700 | 12,015 | Yes |

| 1/2 | M12 | 40 | 54 | 2700 | 12,015 | Yes |

| 9/16, 5/8 over 5/8 |

- | 55 | 75 | 3400 | 15,130 | Yes |

Copyright © 2026 Advancement International Ltd, Aurora Ohio - All Rights Reserved

Advancement International Ltd is a registered company of Ohio, USA

IHI® is the Registered Trademark of International Hydraulics Inc.

LugsDirect.com is owned and operated by Advancement International Ltd.

DUNS # 148692197, REGISTERED WITH CCR, CAGE / NCAGE NUMBER 5A6R9,

A2 WOMAN OWNED SMALL BUSINESS, NAICS 423610, SIC 3643,

Made in the USA from domestic and imported parts. USMCA CERTIFICATES AVAILABLE