Advancement International Ltd.

595 Circlewood, Aurora, OH 44202(USA)

Email: sales@LugsDirect.com

Phone: 330-562-8983 | FAX: 330-562-9990

|

Operated By: Advancement International Ltd. 595 Circlewood, Aurora, OH 44202(USA) Email: sales@LugsDirect.com Phone: 330-562-8983 | FAX: 330-562-9990 |

IHIConnectors |

Brumall Manufacturing Corp. |

Greaves Electrical Connectors |

Accepted forms of payment: |

||||||

|

|||||||||

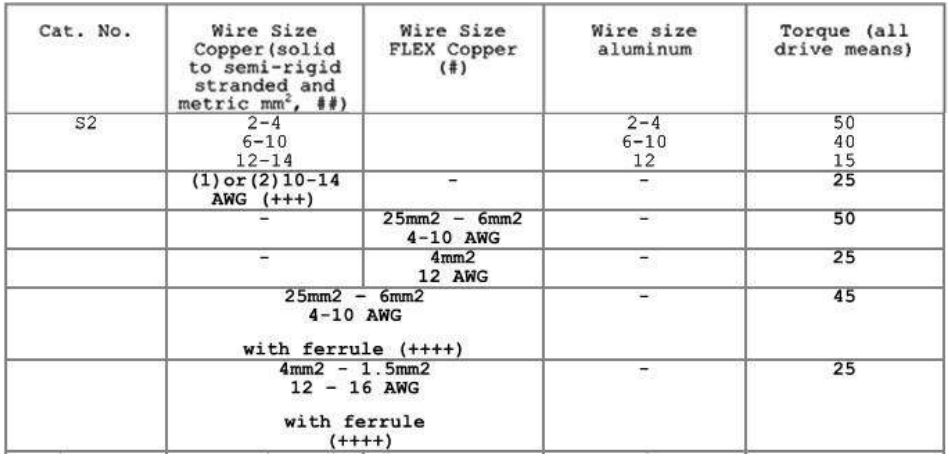

IHI Connectors Cat. Numbers S2 Ferrule Installation Instructions with no pre-crimping of the ferrule to wire.

Copper stranded wire AWG class B to K & mm2 class 2 to 5

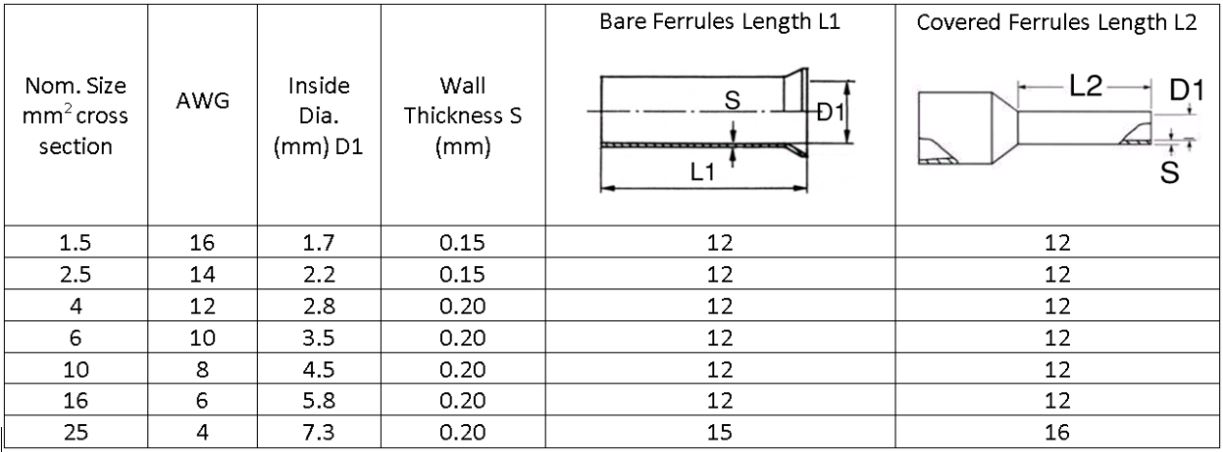

Ferrule construction details

Sleeve (Bare ferrule) – Copper or a copper alloy containing at least 80% copper and be coated with tin. See above for dimension details. To be used with Copper FLEX conductors as shown in the WIRE RANGE RATING table.

Alternate Sleeve (Covered ferrule)– UL486A-B Recognized (ZMVV2) or UL486F Listed (ZMLF).

Copper or a copper alloy containing at least 80% copper and be coated with tin. See above for dimension details. To be used

with Copper FLEX conductors as shown in the WIRE RANGE RATING table below.

S2 Listed AWG 2-14 (16 AWG with ferrule)

(#) FLEX covers stranding classes within G, H, I/DLO, K/MTW for AWG sizes. Metric Class 5 for metric mm2 sizes. (##) mm2 sizes within AWG/kcmil ranges are included. (+++) - No intermixing of wire sizes. No intermixing of stranded and solid wire, i.e., only two No. 14 solid, two No. 14 stranded, two No. 12 solid, two No. 12 stranded, two No. 10 solid and two No. 10 stranded. (++++) Torque Table when using stranded class B, C, G, H, I, DLO, class K, MTW for AWG sizes; and class 2, Class 5 for metric mm2 sizes, copper wire with a user supplied standard copper tubular ferrule (constructed in accordance with UL486F dimensional tables) mounted on the stripped wire without crimping. Assigned Torque Rating include crimping and retaining the wire and ferrule. Factory or field install permitted.

(#) FLEX covers stranding classes within G, H, I/DLO, K/MTW for AWG sizes. Metric Class 5 for metric mm2 sizes. (##) mm2 sizes within AWG/kcmil ranges are included. (+++) - No intermixing of wire sizes. No intermixing of stranded and solid wire, i.e., only two No. 14 solid, two No. 14 stranded, two No. 12 solid, two No. 12 stranded, two No. 10 solid and two No. 10 stranded. (++++) Torque Table when using stranded class B, C, G, H, I, DLO, class K, MTW for AWG sizes; and class 2, Class 5 for metric mm2 sizes, copper wire with a user supplied standard copper tubular ferrule (constructed in accordance with UL486F dimensional tables) mounted on the stripped wire without crimping. Assigned Torque Rating include crimping and retaining the wire and ferrule. Factory or field install permitted.

Copyright © 2025 Advancement International Ltd, Aurora Ohio - All Rights Reserved

Advancement International Ltd is a registered company of Ohio, USA

IHI® is the Registered Trademark of International Hydraulics Inc.

LugsDirect.com is owned and operated by Advancement International Ltd.

DUNS # 148692197, REGISTERED WITH CCR, CAGE / NCAGE NUMBER 5A6R9,

A2 WOMAN OWNED SMALL BUSINESS, NAICS 423610, SIC 3643,

Made in the USA from domestic and imported parts. USMCA CERTIFICATES AVAILABLE