Advancement International Ltd.

595 Circlewood, Aurora, OH 44202(USA)

Email: sales@LugsDirect.com

Phone: 330-562-8983 | FAX: 330-562-9990

|

Operated By: Advancement International Ltd. 595 Circlewood, Aurora, OH 44202(USA) Email: sales@LugsDirect.com Phone: 330-562-8983 | FAX: 330-562-9990 |

IHIConnectors |

Brumall Manufacturing Corp. |

Greaves Electrical Connectors |

Accepted forms of payment: |

||||||

|

|||||||||

FAQ for using ferrules in UL508A Panels and NEC Applications

Q. Why use Ferrules?

1) You want to use FLEX class (G-K, DLO, and class 5), fine stranded wires in a UL486AB lug that is only rated for B and C class wires.

2) You want to protect smaller, class C stranded wires, like #14 gauge, from strand damage.

3) You want to comply with IEC or other standards and agencies (outside USA) that require ferrules on all stranded wire used in direct screw type connectors.

4) You want to use two wires in a UL486AB wire connector that is only rated for one wire.

For more on the use of FLEX wires in UL486A-B lugs without using ferrules see this FLEX Wire FAQ.

Q. What is the purpose of a ferrule?

A. Confirmed by UL486 standards Principal Engineer in 2024, the use of a ferrule:

“The ferrule ‘converts’ a ‘fine stranded’ wire to a solid wire (or in the case of larger size conductors* – specifically sizes 8 AWG and larger) a Class B/C stranded conductor. The ferrules are intended to be used in connectors rated for solid wire (10 AWG and smaller) or Class B/C (stranded) for 8 AWG and larger.”

* “Smaller size conductors” means lighter wire gauge – less current capacity

“Larger size conductors” means heavier wire gauge – higher current capacity

AWG #10 and smaller:

The reason why there is a break point at #10 AWG is because the standard UL486AB test program for NEC code building wire includes #10-14 AWG solid copper wires commonly used in NEC building wiring (USA). Testing for the UL486AB lug generally includes stranded and solid copper wires in the #10-#14 range.

An appropriately rated UL486F (ZMLF) ferrule will “convert” the stranded wire to “solid” wire, and the solid wire ratings on the UL486AB lug are then adequate to allow the termination of a stranded #10-14 AWG copper wire with UL486F ferrule in a UL486AB lug rated only for #10-14 AWG solid copper wires. No ferrule is needed on solid wires.

Ferrules are commercially available with ratings for most stranded classes from B, and C, (NEC) coarse stranded and finer (Flex) classes G, H, I, DLO, K, M (see rating label on ferrule unit container) See Panduit single and twin ferrule spec sheets as an example.

Restrictions on ferrule use when using UL486F (ZMLF) ferrules:

1) As copper ferrules may only be used on copper wires, no ferrule usage with any class of aluminum or CCA copper clad aluminum wire is permitted.

2) Unless wires smaller than #14 AWG are specifically tested under the UL486AB wire connector standard and has rating on the user torque label, then wires smaller than #14 AWG are not covered

However, some smaller screw type “mechanical” connectors sometimes do have rating for wires of #16 AWG or #18 AWG which allows ferrules to be used. Look at the UL rating label for the lug.

Generally, commercial/industrial panel current wiring requires using no less than #14 AWG conductor even if the current draw would permit a smaller conductor.

When using stranded copper wires of smaller sizes, AWG #16 to AWG #20, it is recommended to use appropriately rated ferrules to protect the fine strands where this ferrule rule and rating labels permit solid wire.

AWG #8 and larger:

The standard UL486AB test program for NEC code building wire includes stranded wire classes B and C.

Ferrules are commercially available with gauges of #8 AWG to 1/0 AWG for most copper conductor stranded classes from B, and C, coarse stranded and finer (Flex) classes G, H, I, DLO, K, M (see rating label on ferrule unit container)

As copper ferrules may only be used on copper wires, no ferrule usage with any class of aluminum or CCA copper clad aluminum wire is permitted.

However, the UL486F base standard does not automatically cover wires outside of standing classes B and C, the so called "rigid stranded" NEC code wire classes or class 2 “(r)” in IEC metric wires. Only wire classes in the base standard are tested by UL and other Nationally Recognized Testing Laboratories (NRTL) unless the scope of the testing is widened with an additional testing plan, for the other wire classes. For the full scope of UL486F see the UL White Book on ZMLF Category Bare and Covered Ferrules.

So ONLY ferrules that have been specifically designed and tested to work with fine stranded wires AND specify the fine wire classes, sizes, and installation tool in the product labeling, are allowed to be used to “convert” FLEX class wires to B/C class wires and then terminate in a UL486A-B lug.

Q. How do ferrules allow the termination of two wires into a UL486AB connector that is only rated for one wire?

A. The standard UL486F covers twin ferules, which by their very design convert two wires into one wire.

The scope of UL486F (Edition 3, December 09, 2024, Section / Paragraph Reference: Section 1.2, 1.4) states:

“1.2 This standard applies to ferrules that are intended to facilitate the connection of stranded wire on to devices, such as terminal blocks. Their purpose is to treat stripped wire and prevent turned back strands during installation. They are intended to be used to attach to one stranded copper conductor or two stranded copper conductors of the same size.”

“1.4 When intended for use with two conductors, these ferrules are suitable for use with (2) 6 – (2) 26 AWG, (2) 16 – (2) 0.25 mm2, stranded copper conductors.”

The standard for UL486AB Wire Connectors allows the termination of wires prepared with UL486F ferrules.

UL486AB (Edition 4, March 14, 2025, Section / Paragraph Reference: Section 1.2) states:

1.2 Connectors covered by this Standard are also suitable for use with conductors that are prepared using ferrules evaluated in accordance with CSA C22.2 No. 291-14 / UL 486F, or wire connector adapters evaluated in accordance with this Standard, under the following conditions:

a) Ferrules and adapters are applied in accordance with their ratings and installation instructions.

b) The length of exposed conductive material maintains the strip lengths required by the connector

manufacturer.

Caveats and considerations when using ferrules for to “convert” two wires to one:

1) Twin ferrules under UL486F (ZMLF) are suitable for use with (2) 6 – (2) 26 AWG, (2) 16 – (2) 0.25 mm2, stranded copper conductors. No mixing wire stranding classes or wire gauges.

2) Flex class wires are often bigger in diameter than their B and C class counterparts.

3) A wire prepared with a ferrule takes up a larger amount of space than a bare wire of the same wire size and stranding class. By adding a crimped ferrule to a flex wire your wire may no longer fit in the connector wire hole designed for that wire size in a B or C class wire. With twin ferrules this is doubly true.

4) A twin ferrule essentially changes your wire gauge.

The cross section of two 14 AWG B or C class wires ≠ one 14 AWG B or C class wire.

The cross section of two 14 AWG flex wires ≠ one 14 AWG B or C class wire.

The cross section of two 14 AWG flex wires ≠ two 14 AWG B or C class wires.

5) A wire with a crimped ferrule “converts” to a single B/C/solid wire and must then be installed into the UL486AB lug using the manufacturer’s instructions for installation of a B/C class or solid wire for the newly created wire gauge. This needs to be taken into consideration when determining the torque on the connector label.

Q. How do I know a ferrule is appropriately rated for the wire I am using?

A. UL requires that the ferrule package be labeled with the wire gauge and stranding class, or a scannable QR code that will supply this information to you. See the ZMLF White Book (Product iQ) category for full details of what needs to be on the label of a UL486F ferrule.

Companies that manufacture UL486F Ferrules with B/C and FLEX and metric wire ratings:

(individual products can cover any of these classes but not necessarily all. Check manufacturer product details on each specific ferrule as these details can vary) The UL inspector will want to see the packaging.

Panduit (Panduit catalog ref): Class B, C, G, H, I, DLO, K, and M (does not offer metric classes)

Cembre GmBH (Cembre install ref): Metric Class 2, 5, AWG Class G, and K

Phoenix Contact GmBH: Metric Class 5, 6, and AWG Class B, C, G, H, I, K, and M

Q. Why are temperature ratings of ferrules low for insulated (covered) ferrules?

A. All plastic is separately tested by UL for it’s temperature rating. Bare ferrules are not subject to this scrutiny.

Link to ferrule temp rating page ******************

Q. Do I have to use a ferrule in a UL486A-B lug?

A. A ferrule is only required if required on the UL486AB connector labeling of the lug you are using to terminate your conductor.

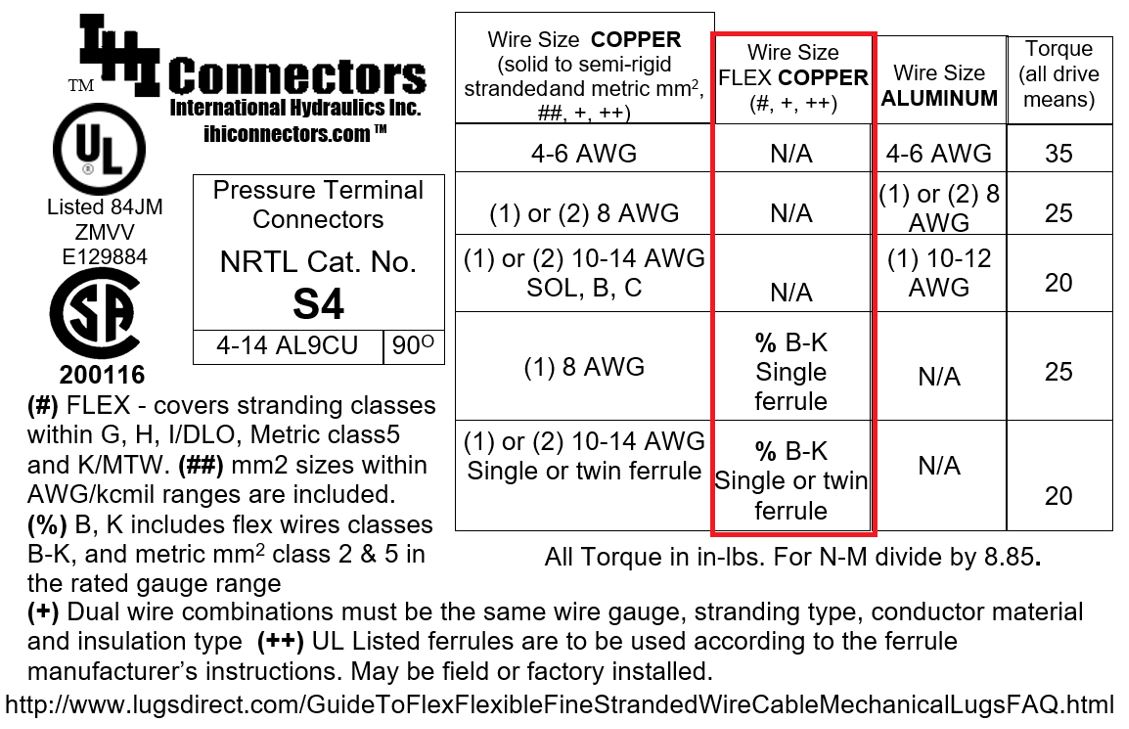

Product Example IHI connector S4 agency label. Note that the only way to use copper FLEX B-K class wire is with the use of a ferrule:

Q. Can I use a ferrule even if the UL486A-B connector does not require it?

A. Yes.

UL486AB (Edition 4, 3/14/2025) Section 1.2 states:

“1.2 Connectors covered by this Standard are also suitable for use with conductors that are prepared using ferrules evaluated in accordance with CSA C22.2 No. 291-14 / UL 486F, or wire connector adapters evaluated in accordance with this Standard, under the following conditions:

a) Ferrules and adapters are applied in accordance with their ratings and installation instructions.

b) The length of exposed conductive material maintains the strip lengths required by the connector manufacturer.”

In short, the wire strip length and ferrule need to meet the wire engagement of the mechanical lug wire hole.

Q. Are the ferrules specified in UL486F made to DIN standard dimensions?

A. Yes. This does not mean all DIN standard ferrules are UL486F rated ferrules. Only ferrules tested and marked as UL486F ferrules are UL486F.

Q. Can I use a ferrule that is not UL486F rated, like a standard DIN ferrule?

A. Only after further UL investigation of the ferrule in the final assembly, which will require further delay and evaluation costs. If there is already a UL486F ferrule that meets the needs of your application, you can skip the time delay and added costs for testing. IHI has some lugs (S2, P2, B2D) that can use DIN ferrules that are not UL486F ferrules.

See Tork-Krimp FAQ for more information on IHI brand connectors that allow the use of specific DIN ferrules, uncrimped, in certain connectors.

Q. Do I have to buy ferrules that are UL rated for the fine stranded classes that I want to use?

A. Yes; UL, NEMA, and NEC have made it completely clear that the use of any wire ferrule that is only rated with base standard UL486F is NOT adequate since this BASE standard does not automatically cover wires outside of standing classes B and C, the so called NEC code wire "rigid stranded" classes. Only wire classes in the base standard are tested by UL and other NRTL's unless the scope of the testing is widened with an additional testing plan, for the other wire classes.

So ONLY ferrules that have been specified and tested to work with fine stranded wires AND specify the fine wire classes, sizes, and installation tools in the product labeling, are allowed to be installed in panels or other UL / NEMA / NEC controlled electrical installations.

For more information on FLEX classes of wire used in UL486A-B lugs, see the FLEX Wire FAQ.

Q. Do ferrules change the wire range of a wire connector?

A. Yes. Ferrules typically decrease the size capacity of the lug since the wire, with a crimped ferrule takes up a larger inscribed circle than a bare wire. The common trapezoidal and square cross sections are "a square peg in round hole" that may require a larger lug than otherwise might be necessary. Hexagonal crimp tooling is the best fit for a round hole but be sure you know what tools were used to crimp a ferrule in the manufacturer's UL testing, since it will also need to be used in any subsequent UL covered use of that ferrule.

Ferrules are more commonly used on smaller gauge, lower power, fine stranded wiring for DIN rail type applications.

For larger gauge, higher power wire cabling, the use of ferrules is less common or applicable, but nevertheless, if you want to qualify a ferrule for an IHI FLEX lug you are free to do so under the NRTL assembly testing program having already in hand the qualification of the lug itself for flex wire.

Post crimp ferrule ref sheet

Q. What is the SCCR rating of a ferrule?

A. Ferrules do not have a SCCR rating so follow one or all of these:

1) The default rating of the UL486AB wire connector being used which is 10,000 Amps for UL466AB wire pressure connectors.

2) The actual tested or calculated rating for the panel using the appropriate methodologies such as UL508A

3) Maximum SCCR rating under UL486F scope clause 1.9 2024

1.9 Ferrules covered by this standard may be used with equipment having short circuit ratings of:

a) 85,000 A maximum, or

b) 100,000 A maximum if supplied by an overcurrent protective device, and the equipment short circuit current rating, divided by the number of conductors per phase, results in a current of 50,000 A or less per conductor.

View the UL486F Scope and UL White Book on ZMLF Category Bare and Covered Ferrules

References: UL LLC, NEC CODE, NFPA.

Please find more information at ULStandards.com and NFPA.org

This information is provided for educational use only and no claims are made for its completeness, accuracy, and may not be updated.

Copyright © 2025 Advancement International Ltd, Aurora Ohio - All Rights Reserved

Advancement International Ltd is a registered company of Ohio, USA

IHI® is the Registered Trademark of International Hydraulics Inc.

LugsDirect.com is owned and operated by Advancement International Ltd.

DUNS # 148692197, REGISTERED WITH CCR, CAGE / NCAGE NUMBER 5A6R9,

A2 WOMAN OWNED SMALL BUSINESS, NAICS 423610, SIC 3643,

Made in the USA from domestic and imported parts. USMCA CERTIFICATES AVAILABLE